product

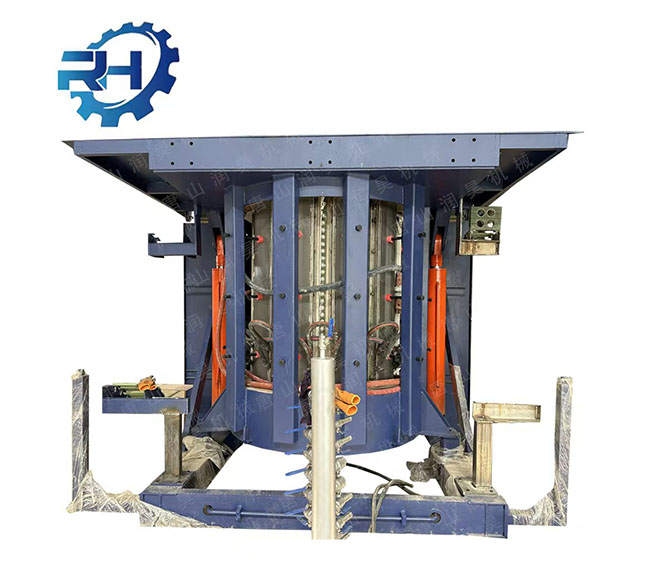

Steel shell medium frequency furnace

The intermediate frequency furnace is mainly composed of a power supply, an induction coil, and a crucible made of refractory materials inside the induction coil.

Process

Introduction

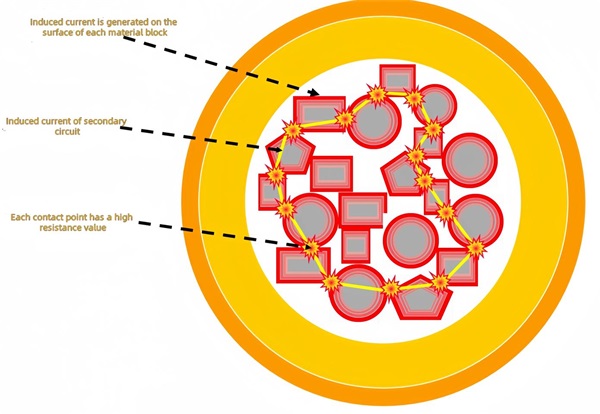

The intermediate frequency furnace generates intermediate frequency power through the rectification and inversion of controllable silicon, which is sent to the furnace coil. The intermediate frequency electromagnetic field is generated in the middle of the furnace (coil), causing eddy currents in the metal inside the furnace. The eddy currents then generate a large amount of heat energy in the metal, causing it to melt.

The intermediate frequency furnace is mainly composed of a power supply, an induction coil, and a crucible made of refractory materials inside the induction coil. The crucible contains a metal charge, which is equivalent to the secondary winding of a transformer. When the induction coil is connected to an AC power supply, an alternating magnetic field is generated inside the induction coil, and its magnetic lines cut through the metal charge in the crucible, generating an induced electromotive force in the charge. Due to the closed loop formed by the charge itself, the point of this secondary winding has only turns and is closed. So induced current is generated simultaneously in the furnace charge, and when the induced current passes through the furnace charge, it heats it up and causes it to melt.

The medium frequency furnace is also a type of induction cooker, and its working process is as follows: first, a three-phase AC power is rectified (using thyristors) into single-phase DC power through an inverter power supply, and then inverted into a 500-1000Hz medium frequency pulse AC power through an inverter bridge. Then, a magnetic field is formed through the copper coil inside the furnace, which generates eddy currents in the steel inside the coil. The eddy currents flow through the heated steel, generating heat and achieving the purpose of melting steel.

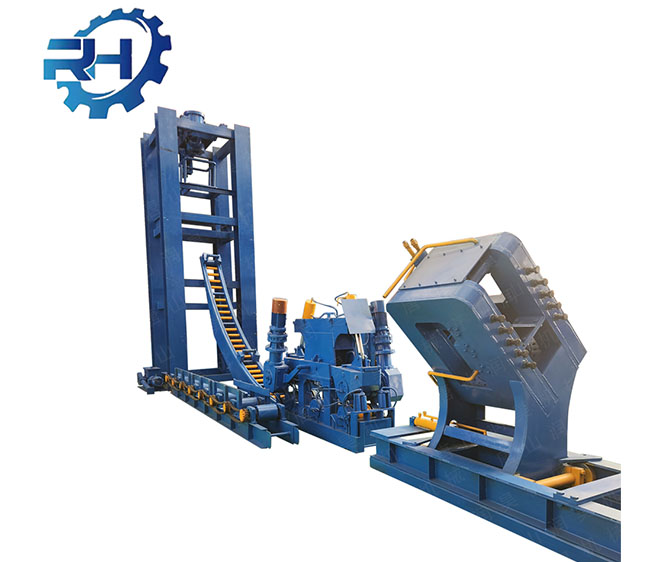

Smelting site

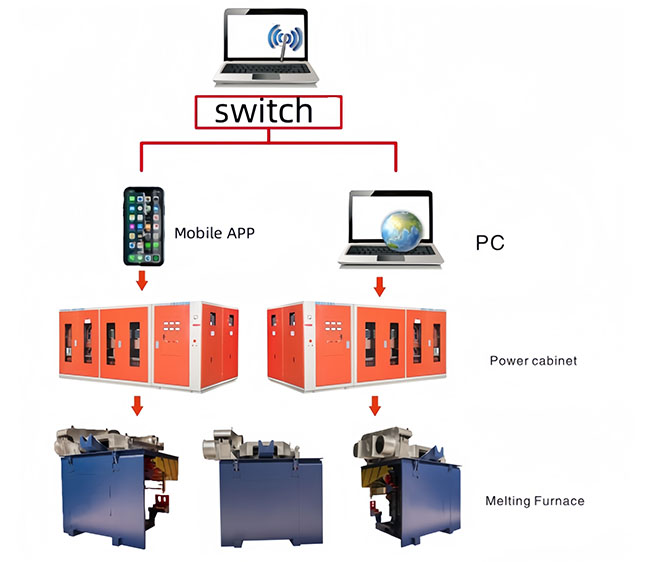

DISTRIBUTION SYSTEM the series resonant one to two power cabinet can distribute the power of two furnaces arbitrarily within the rated power, while keeping one furnace insulated and the other melted (or melting two furnaces with the same power).

Modular design of series resonant power supply cabinet with wide copper bars and 12 and 24 pulse rectification.

Intelligent melting

Automatic oven drying, cold furnace start-up, fault diagnosis, fault information display and storage, operation information display, system status display, etc. The system achieves remote monitoring, automatic alarm, online diagnosis and maintenance through Ethernet communication module for data transmission, ensuring the integration of management and operation. Collecting massive amounts of data can also detect security risks in advance, greatly reducing the cost of product maintenance in the later stages. It can also be connected to the company’s MES system.

Operating System

The computer operating system remote operating system is equipped with a large-sized touch screen, which includes functions such as automatic baking, cold furnace start, automatic insulation, intelligent melting management, and display and storage of fault information.

The power cabinet is installed in the basement, and the remote operating system is placed on the stove platform to operate the power supply. The operation is very simple, just start or stop the dial.

This system can monitor various electrical parameters during equipment operation, including phase voltage, current, and active power. Active power, reactive power, power factor, working time, power consumption and other very practical parameters, especially for power factor, there are relatively high requirements for power consumption enterprises in various regions. The high or low power factor is closely related to the working attitude of the equipment. Through this system, we can clearly know our own power consumption status and make timely adjustments.

related products

All Products

Get in Touch

Got questions about the product? Leave your contact info below, and our experts will get back to you with answers.

Here, You’ll Find More Than Just Services, You’ll Find Friends

Address

Daling Gong, Fengrun District, Tangshan City, Hebei Province, China