product

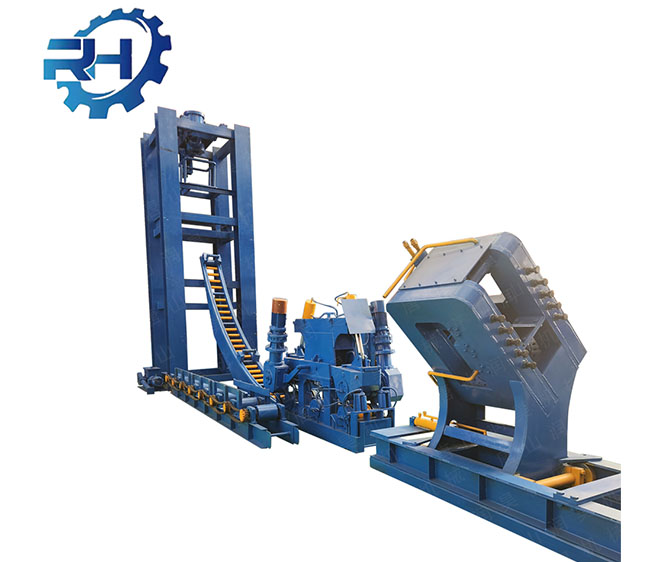

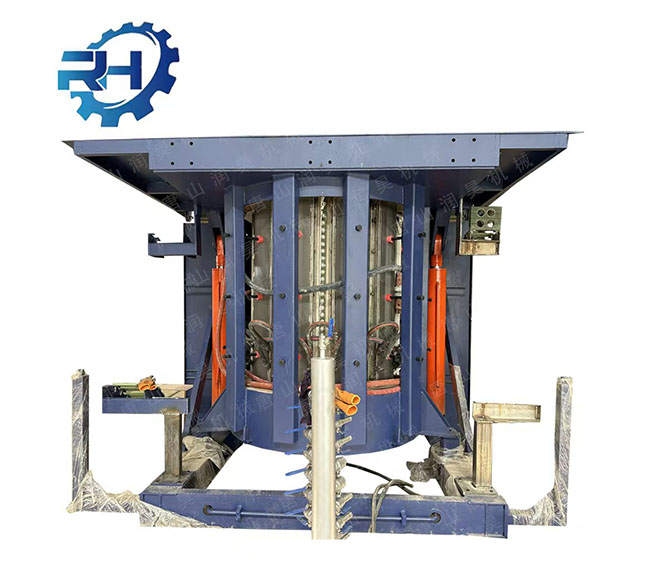

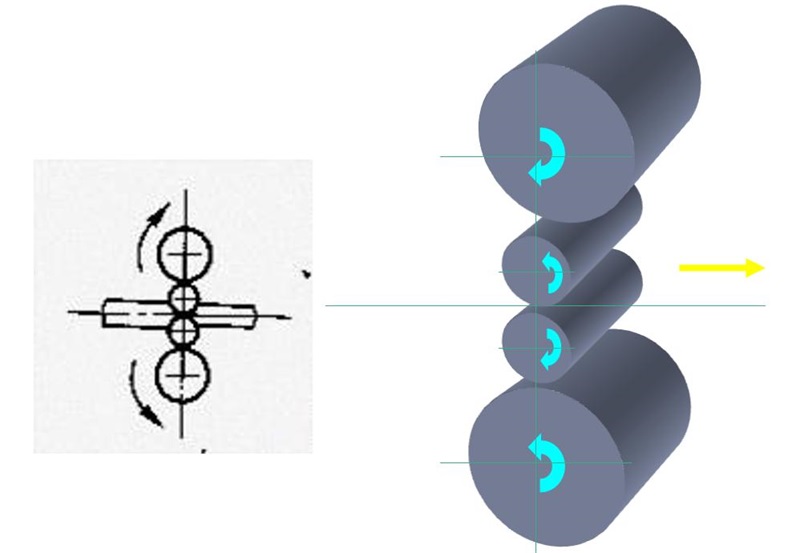

Four roll rolling mill

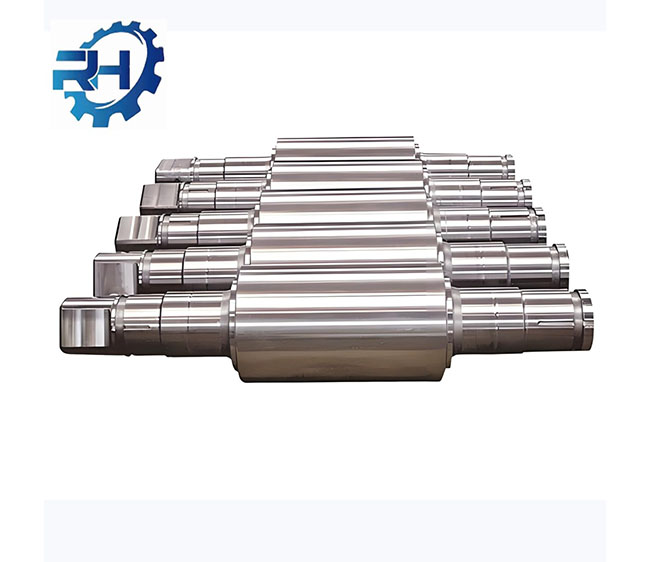

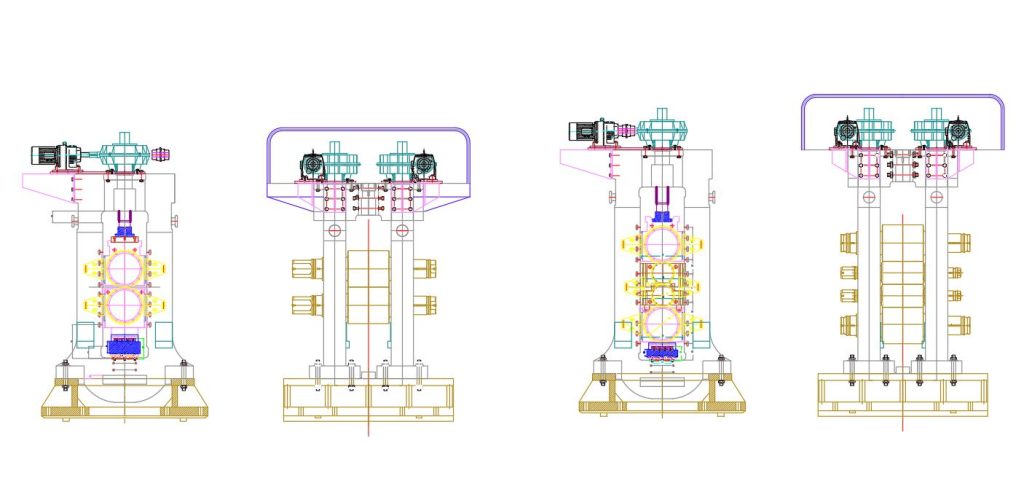

The equipment consists of two working rollers and two support rollers.

Process

Introduction

The process of plastic deformation and shape change of metal sheet by the pressure and friction of four rollers on the metal sheet. The equipment consists of two working rollers and two support rollers. The working roller is the main working roller, while the support roller plays an auxiliary and supporting role. The rolling mill begins to rotate, and the two working rolls rotate relative to each other, forming a pair of interacting forces that press against the metal sheet. Due to the consistent rotation speed and direction of the rollers, the metal sheet is subjected to plastic deformation caused by the compression of two working rollers. Among them, the top working roller presses downwards, and the bottom working roller presses upwards.

Structural diagram

Way of working

Product Display

| Name | Model | Product drawing |

| Angle steel | 20~250 |  |

| Channel steel | 50~400 |  |

| I-beam | 100~630 |  |

| H-beam | 150~750 |  |

| Rail steel | 8kg/m~120kg/m |  |

| Rebar | Φ10~φ32 |  |

| Round steel | Φ10~250 |  |

| Wire rod | Φ5.5~Φ14 |  |

| Flat steel | 12×4~200×30 |  |

| square steel | 8-200 |  |

| Strip steel | 20×1~600×20 |  |

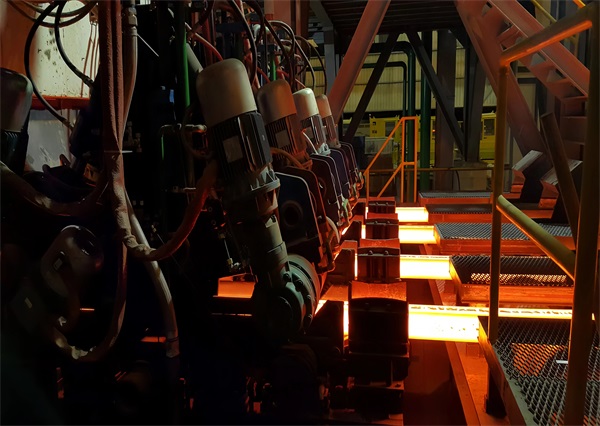

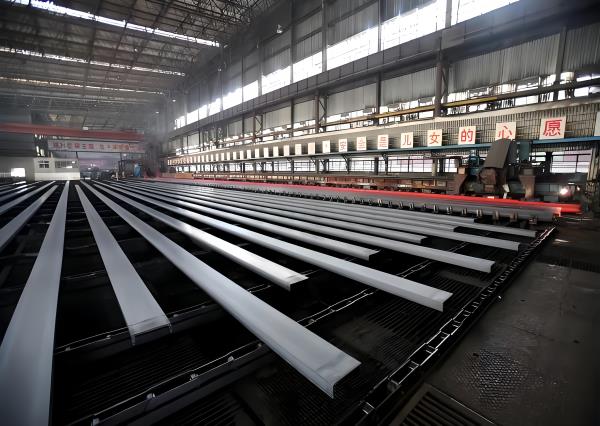

On site production line

related products

All Products

Get in Touch

Got questions about the product? Leave your contact info below, and our experts will get back to you with answers.

Here, You’ll Find More Than Just Services, You’ll Find Friends

Address

Daling Gong, Fengrun District, Tangshan City, Hebei Province, China