product

Short stree rolling mill

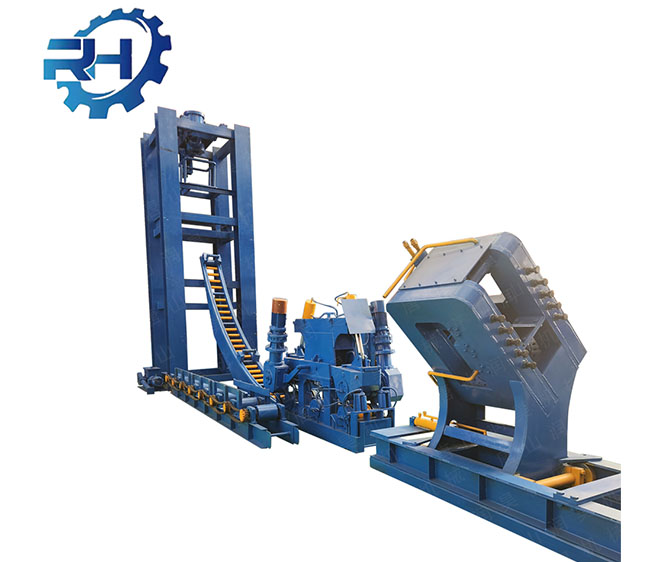

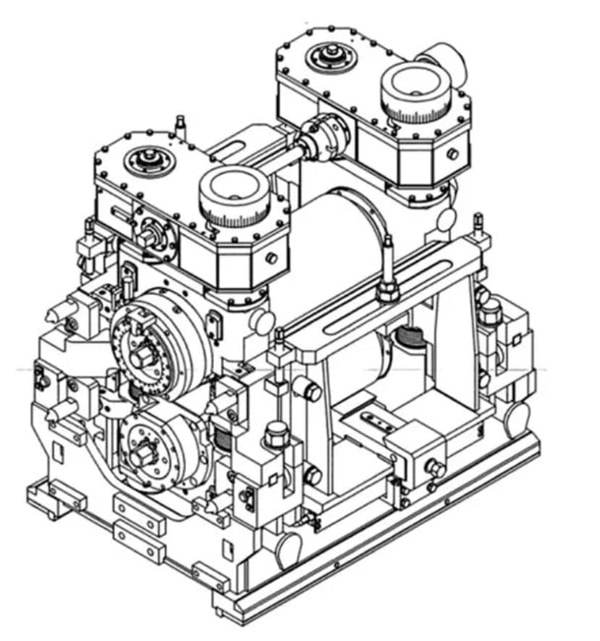

The short stress line mill, also known as the non memorial archway mill, is a kind of mill with simple operation, convenient disassembly and high strength and rigidity.

Advantage

Introduction

The short stress line mill, also known as the non memorial archway mill, is a kind of mill with simple operation, convenient disassembly and high strength and rigidity.

The high stiffness of the rolling mill ensures high precision of the product, making it easy to achieve negative deviation rolling and symmetrical adjustment. This is of great significance for stable operation, improving work efficiency, saving time for maintenance and replacement of guide beams, reducing operational accidents, avoiding process accidents such as rolling bends, impacts, and roller entanglements, and improving the service life of guide beams.

Structure

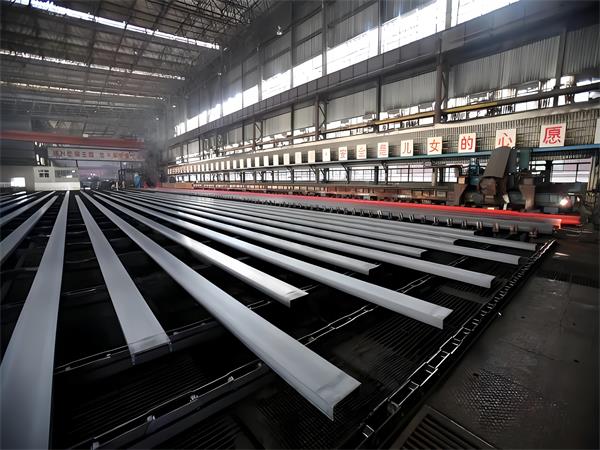

This type of rolling mill can be used to produce various types of steel, including roughing, intermediate rolling, and finishing rolling.

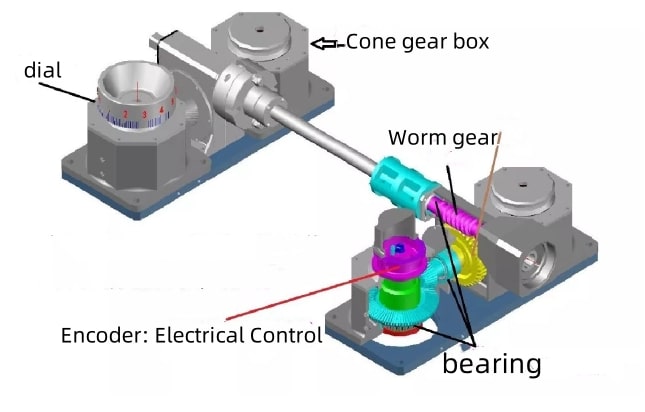

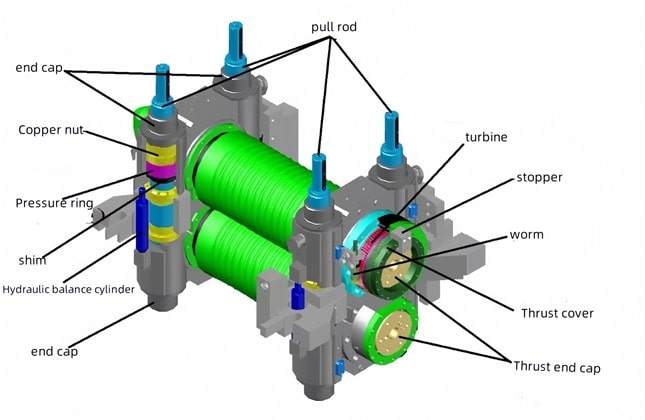

Pressing mechanism

It mainly uses worm gear, worm gear, and gear to drive the rod to rotate and achieve synchronous adjustment of the roll gap of the rolling mill. It can be adjusted simultaneously on the operating side and transmission side, or it can be adjusted unilaterally by disconnecting the connecting shaft. The entire pressing mechanism, under the joint action of mechanical, hydraulic, and electrical components, can remotely adjust the roller gap accurately.

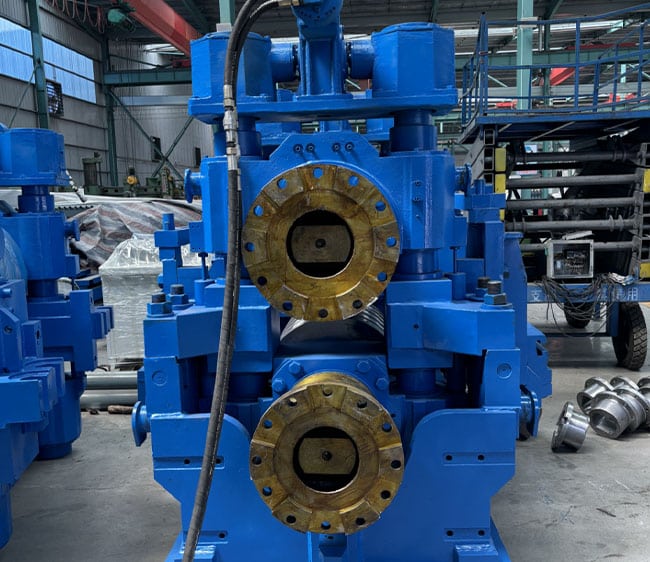

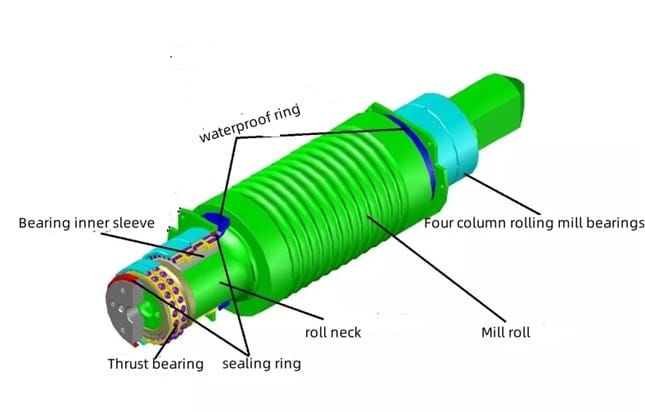

Mill roll assembly

The rolling mill can be divided into two parts: the transmission side and the fixed side, each consisting of an upper and lower box body. The four boxes bear the radial and axial forces transmitted from the rolling mill bearings, and transmit them to the tension rod to form a stress loop. The box and tie rod of the rolling mill are the main working components of the rolling mill. The transmission side box of the rolling mill is a free end that only bears radial forces; In addition to installing four rows of bearings to withstand radial forces, the operating side box is also equipped with thrust bearings to withstand axial forces; The upper box on the operating side is equipped with worm gears and worm mechanisms that can be adjusted axially, with adjustment amounts mostly within ± 3mm; The lower roller cannot be adjusted axially.

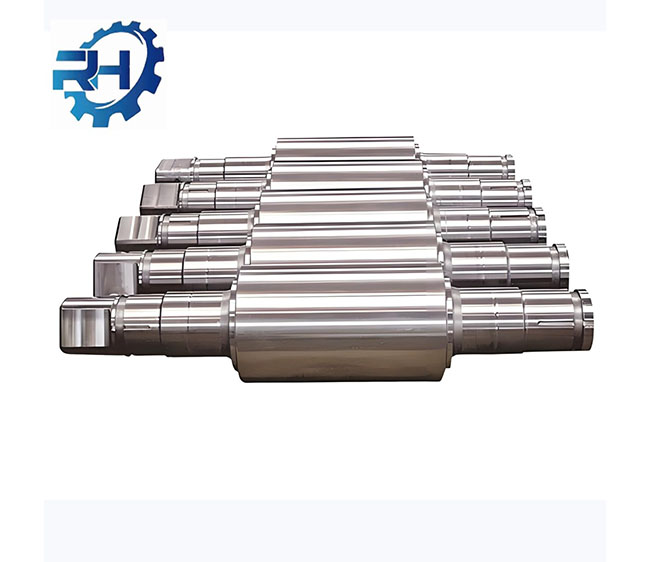

Assembly of pull rod and box

Pull rod and copper nut are the main working parts of the rolling mill under force. The rolling mill drives the upper and lower boxes to move symmetrically by rotating the copper nut installed on the pull rod, thereby achieving symmetrical adjustment of the rolling roll gap. The biggest advantage of this adjustment method is that the rolling line is stable and unchanged, which can avoid rolling and quality accidents caused by misalignment between the rolling line and the hole center line, greatly reducing the dependence on the technical level of steel rolling adjustment workers and simplifying the rolling process. Thus achieving the goal of reducing rolling accidents and improving product accuracy.

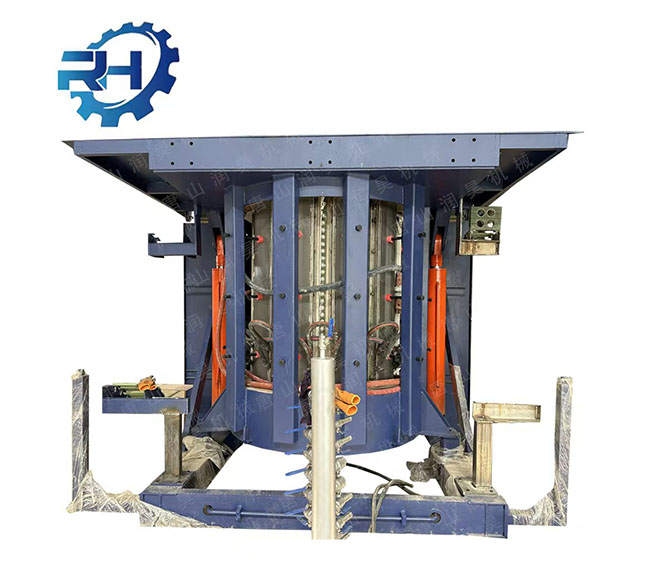

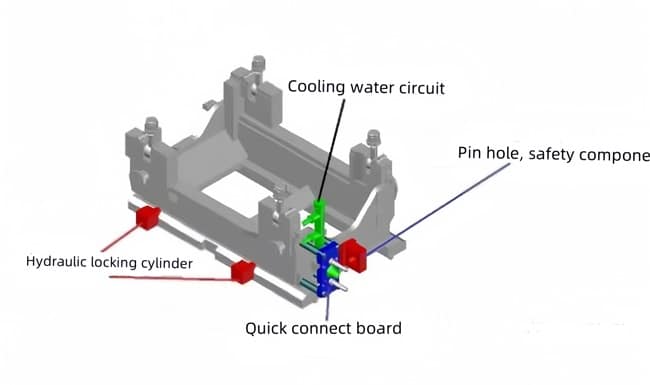

Base

The rolling mill rod is fixed to the base along with the box through the middle frame. The main task is to fix the rolling mill base on the rolling line through four locking cylinders fixed on the foundation. The base of the rolling mill is not subjected to rolling force, only tilting force. By quickly connecting the water, oil, and gas interfaces on the plate, the required working media such as oil, water, and gas during rolling production are provided to various parts of the rolling mill.

related products

All Products

Get in Touch

Got questions about the product? Leave your contact info below, and our experts will get back to you with answers.

Here, You’ll Find More Than Just Services, You’ll Find Friends

Address

Daling Gong, Fengrun District, Tangshan City, Hebei Province, China