product

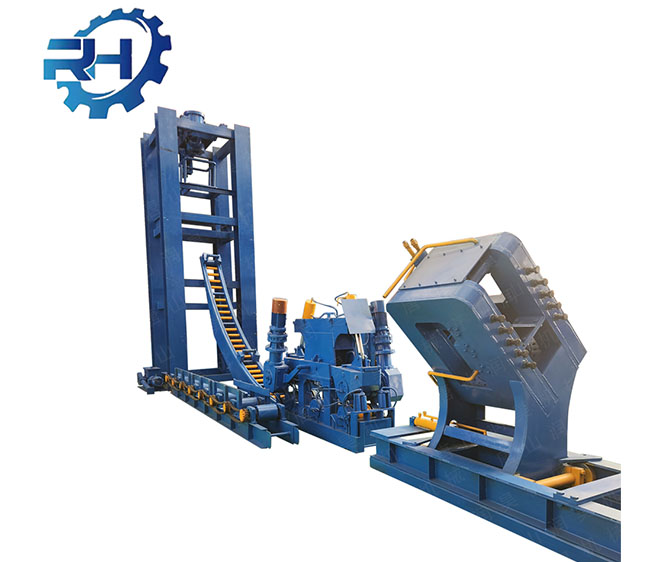

Universal rolling mill

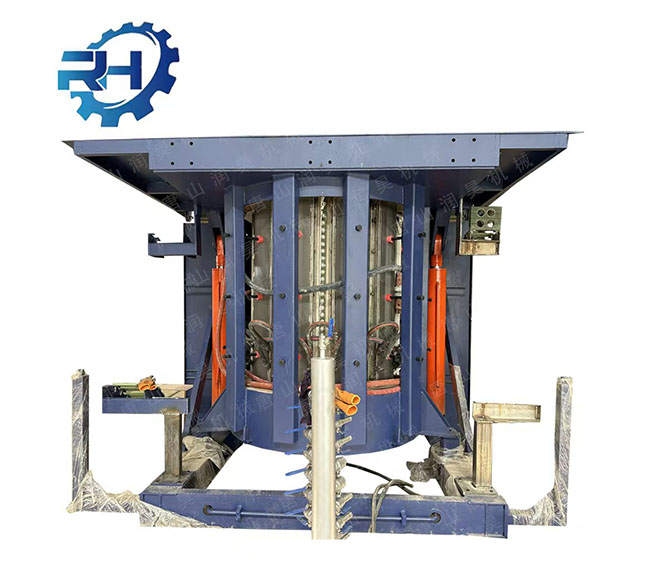

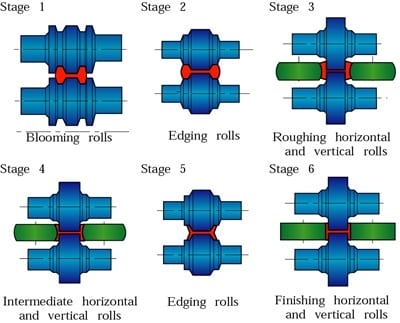

The structure of a universal rolling mill is complex and precise, with the most prominent feature being the configuration of its rolling mill rolls.

Application

Introduction

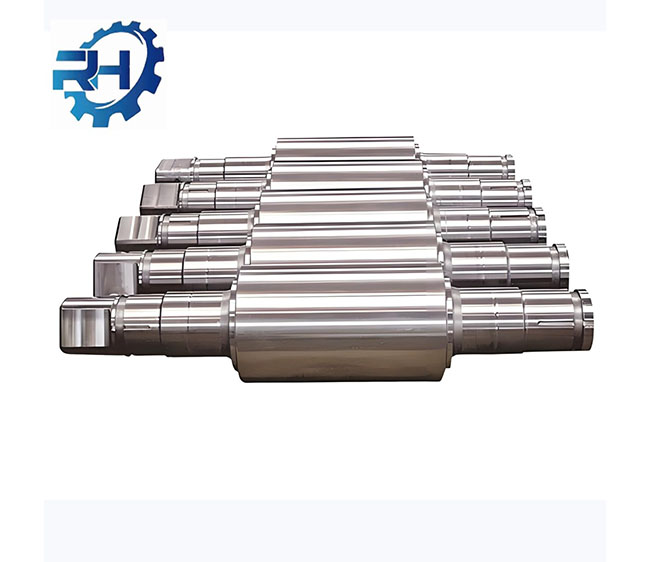

The structure of a universal rolling mill is complex and precise, with the most prominent feature being the configuration of its rolling mill rolls. The rolling mill is the core component of the rolling mill, directly responsible for the rolling work of steel. According to the design and functional requirements of the rolling mill, the number, shape, and arrangement of rolling rolls will vary. Generally speaking, a universal rolling mill consists of at least two rolling rolls, which can achieve multi-directional and multi angle rolling of steel through precise adjustment and control.

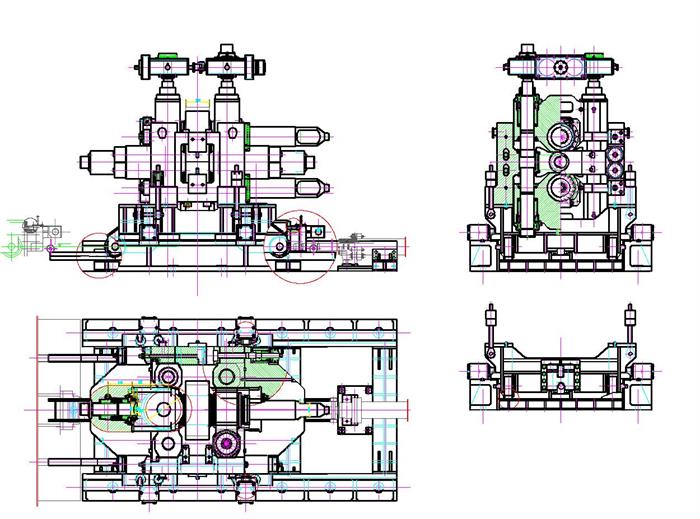

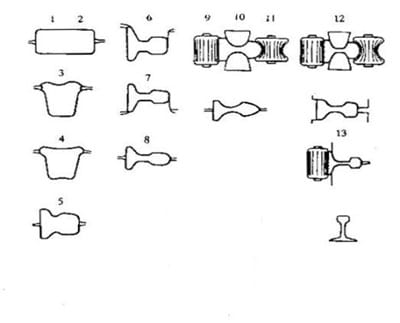

Structural diagram

Product Display

| Name | Model | Product drawing |

| Angle steel | 20~250 |  |

| Channel steel | 50~400 |  |

| I-beam | 100~630 |  |

| H-beam | 150~750 |  |

| Rail steel | 8kg/m~120kg/m |  |

| Rebar | Φ10~φ32 |  |

| Round steel | Φ10~250 |  |

| Wire rod | Φ5.5~Φ14 |  |

| Flat steel | 12×4~200×30 |  |

| square steel | 8-200 |  |

| Strip steel | 20×1~600×20 |  |

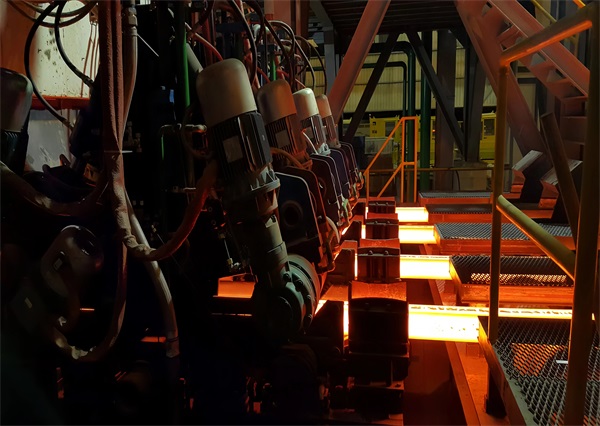

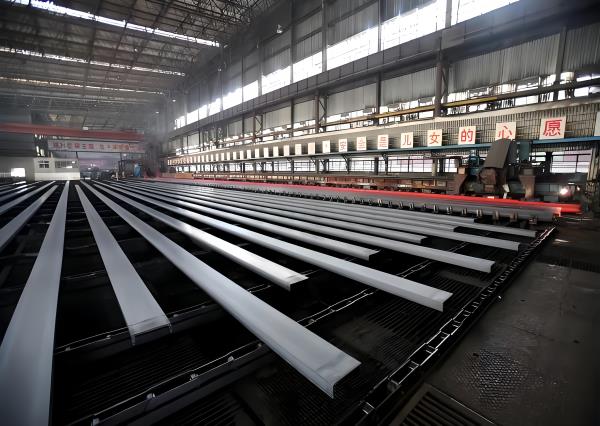

On site production line

related products

All Products

Get in Touch

Got questions about the product? Leave your contact info below, and our experts will get back to you with answers.

Here, You’ll Find More Than Just Services, You’ll Find Friends

Address

Daling Gong, Fengrun District, Tangshan City, Hebei Province, China