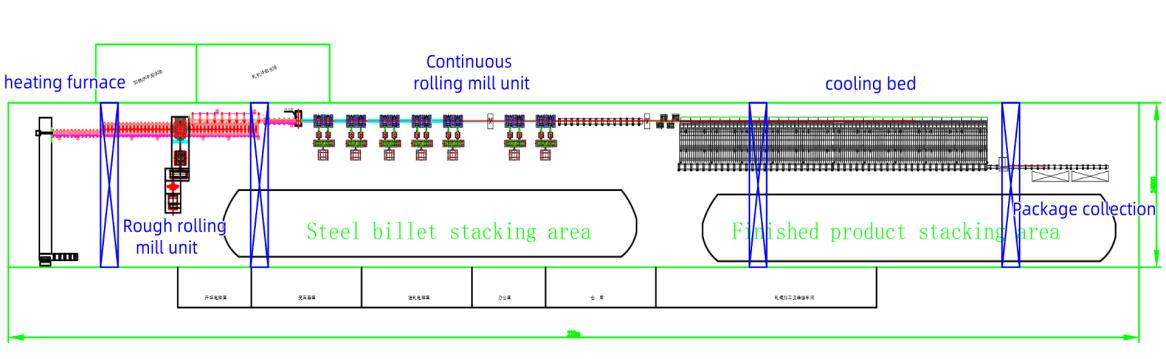

Production Process Diagram

Raw material selection for the production line: 100 * 100-150 * 150 steel billets, production line with diameter 10-32 threaded steel, annual output of 100000-150000 tons;

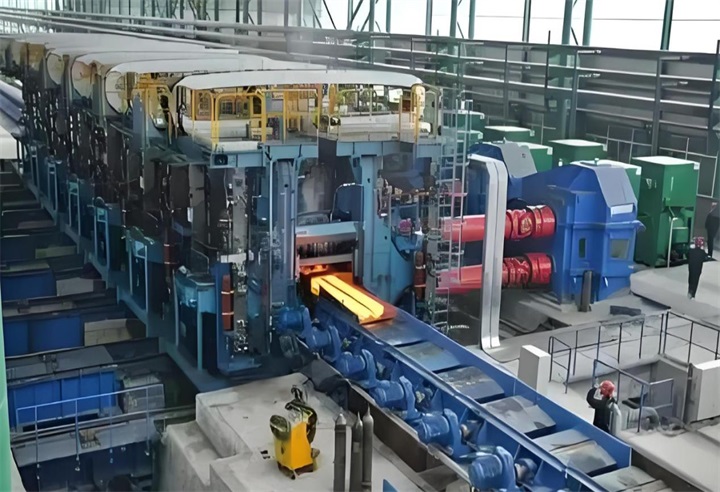

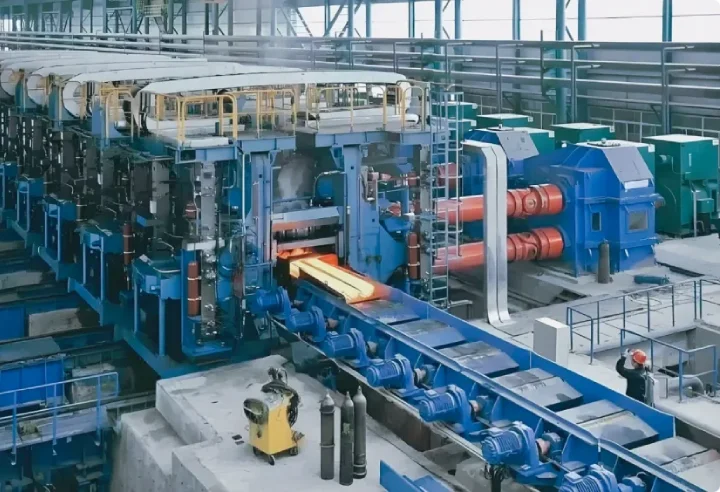

The steel billet is heated to 1150 ℃ through a heating furnace and fed into a three roll roughing mill by a conveyor roller for reciprocating rolling. Then, irregular heads are cut off using a cutting head, and the steel is sequentially fed into 6 sets of intermediate rolling units and 8 sets of precision rolling units to be rolled into finished threaded steel products. After being uniformly cooled by a continuous step cooling bed, the hot threaded steel is cut, collected, packaged, and stored in sections and lengths.

Finished steel display