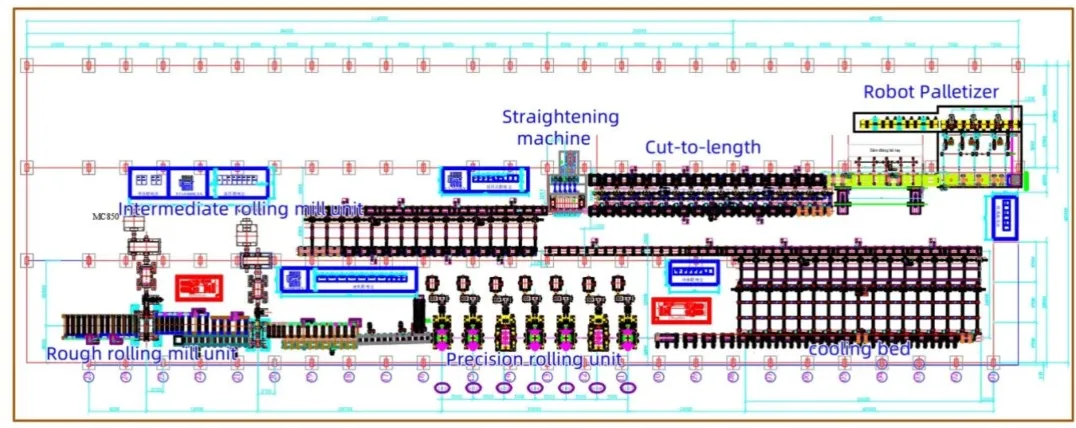

Production Process Diagram

Raw material selection for the production line: The raw materials used are square or rectangular billets, and the size of the billets can be adjusted according to the production output. The annual output is about 200000 to 600000 tons. The heating furnace uses gas or heavy oil as fuel.

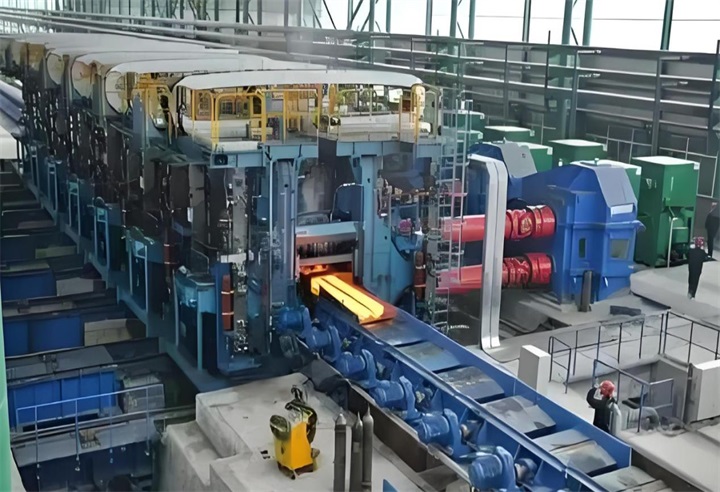

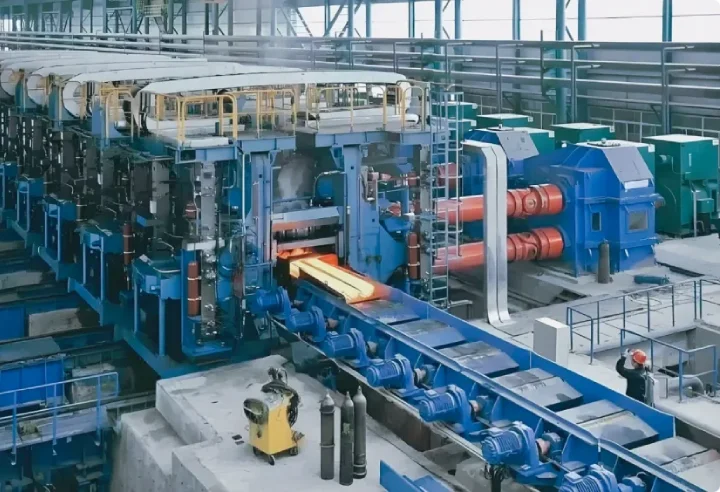

The steel billet is heated to 1150 ℃ by a heating furnace and then fed into a three roll roughing mill for reciprocating rolling by a conveyor roller. Then, the irregular head and tail are cut off by a flying shear, and the rolled pieces are sequentially fed into a universal rolling mill and an edge rolling mill to be rolled into various shaped steel products. After uniform cooling in a continuous stepped cooling bed, the whole is straightened and sawed, collected, packaged, and stored in sections.

Process Summary

Steel Billet Heating

Rough Rolling

Precision Rolling

Cooling of Hot-Rolled Products

Cutting of Finished Products

Straightening

Product Packaging

Storage